Catalog

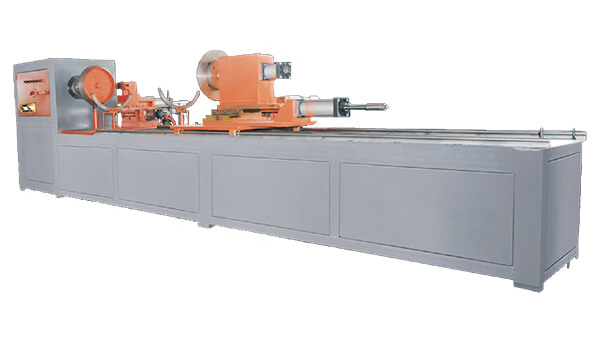

Application: Automatic flanging for inner tank two ends

Detail

Description:

Adopt PLC automatic program control system. Full-automatic to carry out fast flanging at both ends at the same time, installing bracket automatic lifting function, which can make the inner liner automatically set into the flanging mold, installing rack and pinion locking function, which can make the rear flanging device firmly fixed at one point and not easy to slide. Installation of precision linear guide rail ensures the coaxiality of the front and rear flanging device. The pulling wheel is made of Gr12 high hardness mold steel with oil quenching heat treatment. The electrical components are made of Omron and the cylinders are made of Taiwan Yadek.

Parameter:

Please contact us

For cooperation

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Certificate

Application: Automatic flanging for inner tank two ends

Description:

Adopt PLC automatic program control system. Full-automatic to carry out fast flanging at both ends at the same time, installing bracket automatic lifting function, which can make the inner liner automatically set into the flanging mold, installing rack and pinion locking function, which can make the rear flanging device firmly fixed at one point and not easy to slide. Installation of precision linear guide rail ensures the coaxiality of the front and rear flanging device. The pulling wheel is made of Gr12 high hardness mold steel with oil quenching heat treatment. The electrical components are made of Omron and the cylinders are made of Taiwan Yadek.

Parameter:

DISCOVER YOUR DREAM

MACHINERY TODAY

+86-18652546893

+86-18652546893